Contact Us

Address: Xiaozhan Huangtai Industrial Park, Jinnan District, Tianjin

Telephone:+86-022-88629358

Mobile:+86-13389918661

E-mail:sales@xsmfj.com

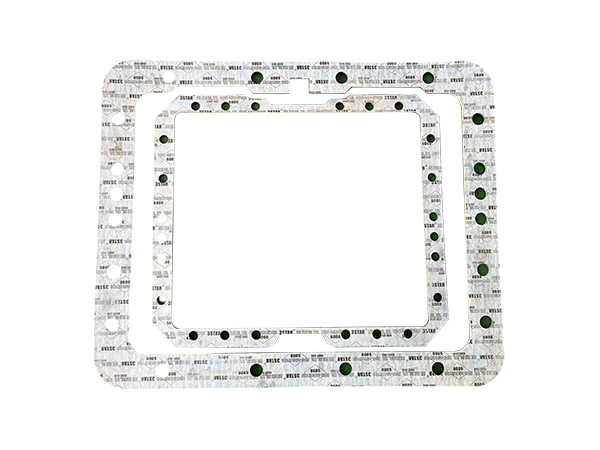

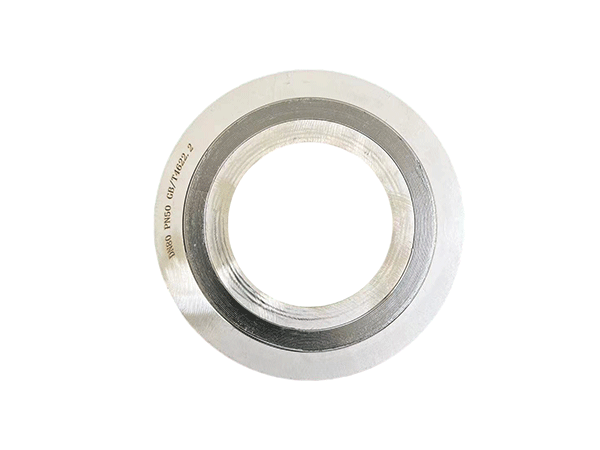

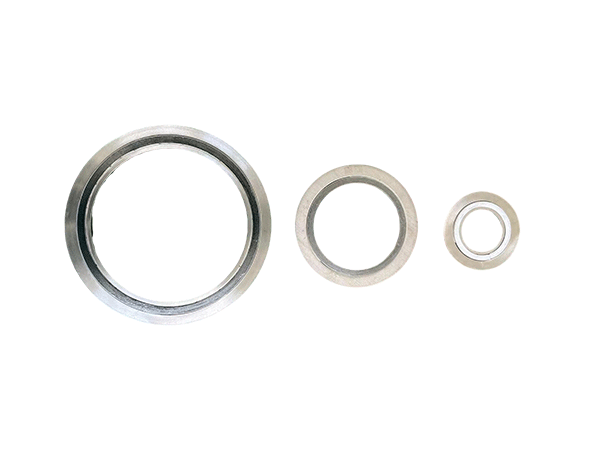

Coated Gasket

- Commodity name: Coated Gasket

- Product Description

-

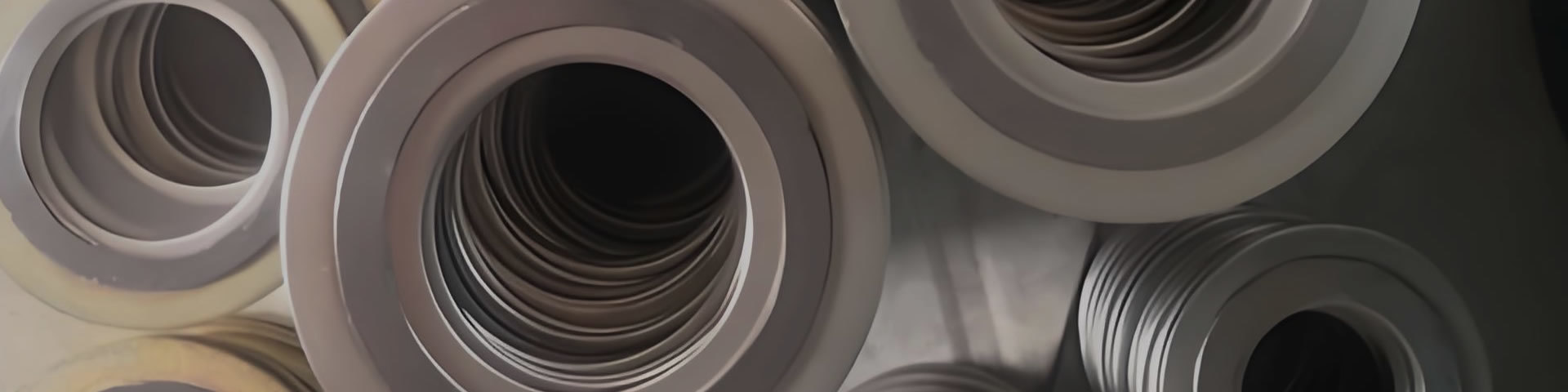

Graphite composite gasket

DDDDDD graphite ring adopts flexible graphite belt or flexible graphite packing, which is molded into ring products of different sizes. Adapt to hot water, high temperature, high pressure steam, heat exchange fluid, nitrogen, organic solvents, hydrocarbons, low temperature liquid and other media. Used for compressors, pumps, valves, chemical instruments, meters, etc. Pressure (Mpa):25 temperature (℃):-200~850 linear velocity (m/s):30 PH value: 0~14 graphite rings are divided into flexible graphite and carbon-graphite rings. Carbon-graphite rings are mainly used in the sealing of mechanical rotating parts. The carbon-graphite ring has the characteristics of high temperature resistance, corrosion resistance and wear resistance.

graphite ring

English name: Graphite ring

The flexible graphite belt or flexible graphite packing is made into ring products of different sizes by molding.

Adapt to hot water, high temperature, high pressure steam, heat exchange fluid, nitrogen, organic solvents, hydrocarbons, low temperature liquid and other media.

Used for compressors, pumps, valves, chemical instruments, meters, etc.

Pressure (Mpa):25 temperature (℃):-200~850Line speed(m/s):30 PH: 0~14

Graphite rings are classified into flexible graphite and carbon-graphite rings.

Carbon-graphite rings are mainly used in the sealing of mechanical rotating parts.

The carbon-graphite ring has the characteristics of high temperature resistance, corrosion resistance and wear resistance.

graphite ring performance and characteristics:

1. The graphite ring has good self-lubrication

2. High coefficient of rebound of graphite ring

3. The graphite ring can be cut at 45 ° according to user needs

Previous

Next

Consultation