Contact Us

Address: Xiaozhan Huangtai Industrial Park, Jinnan District, Tianjin

Telephone:+86-022-88629358

Mobile:+86-13389918661

E-mail:sales@xsmfj.com

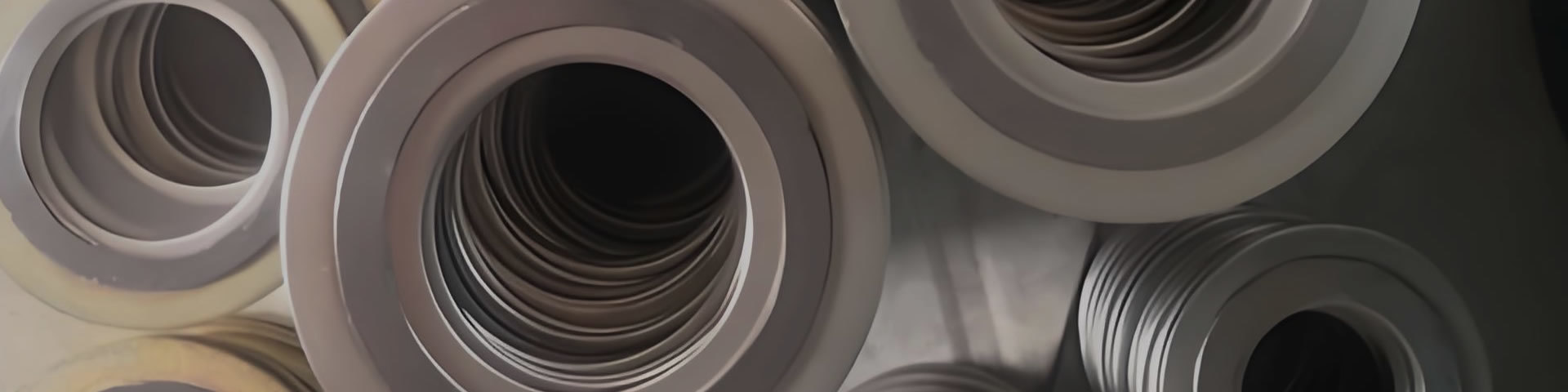

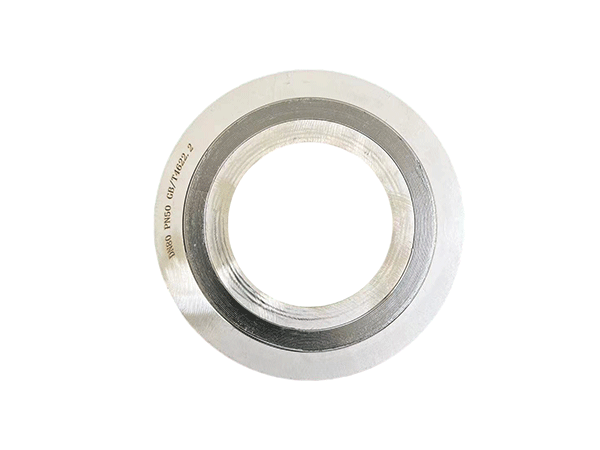

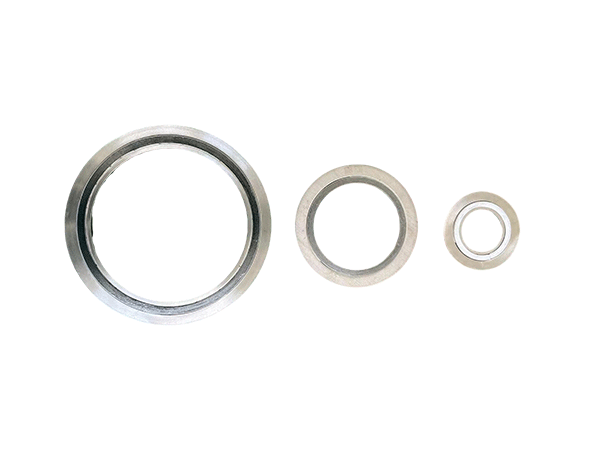

Winding gasket

- Commodity name: Winding gasket

- Product Description

-

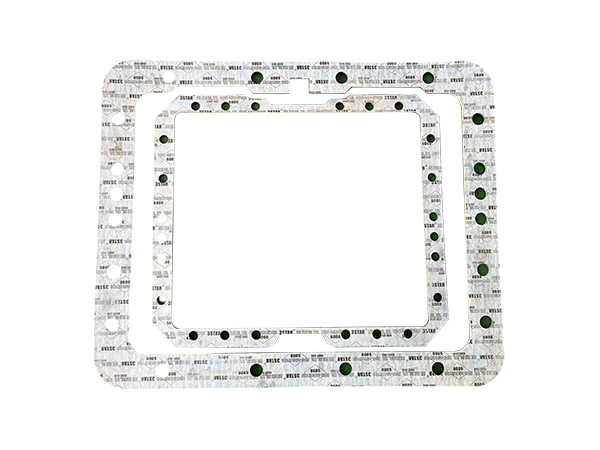

The wound gasket is the gasket with the best resilience in the semi-metal sealing gasket. The structure density of the wound gasket can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. The surface accuracy of the flange sealing surface contacted by the wound gasket is not high.

Scope of application: metal graphite wound gasket is suitable for all kinds of corrosive chemical fluids such as strong alkali, hydrochloric acid, sulfuric acid and other strong corrosive liquids, organic solvents, liquid nitrogen, etc. It is widely used in petroleum, chemical industry, chemical fiber, coal mining, power generation, static sealing components at flange connections of pipelines, valves, pumps, heat exchangers, towers, manholes, hand holes and other industrial equipment such as metallurgy.

Features: Metal graphite wound gasket has good compression resilience, suitable for sealing parts with severe alternating temperature and pressure, and has excellent characteristics such as good impermeability, long service life and maintenance-free.

performance and characteristics

1. Wide range of applicable working conditions. Can withstand high temperature, high pressure and adapt to the use of ultra-low temperature or vacuum conditions. By changing the material combination of the gasket, the problem of chemical corrosion of the gasket by various media can be solved.

2. Strong stress compensation ability. In the temperature, pressure fluctuations frequently on the station, the sealing performance is stable and reliable.

3. Excellent sealing performance.

4. The surface accuracy of the flange sealing surface in contact with the gasket is not high.

5. Easy installation, low gasket pre-tightening pressure.

Previous

Next

Consultation