Contact Us

Address: Xiaozhan Huangtai Industrial Park, Jinnan District, Tianjin

Telephone:+86-022-88629358

Mobile:+86-13389918661

E-mail:sales@xsmfj.com

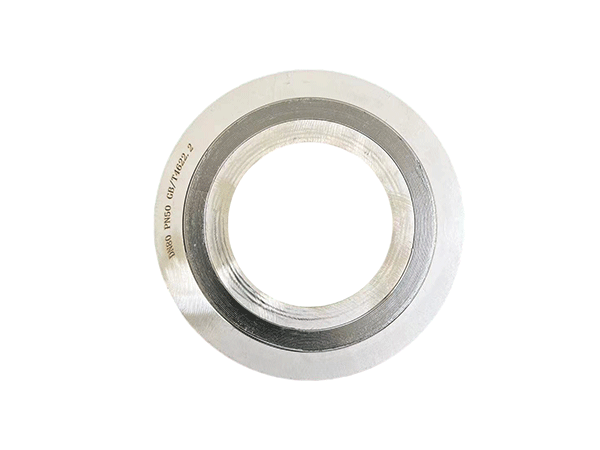

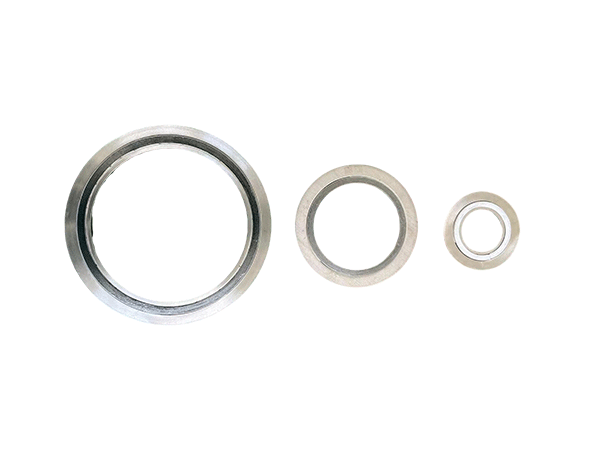

Corrugated composite gasket

- Commodity name: Corrugated composite gasket

- Product Description

-

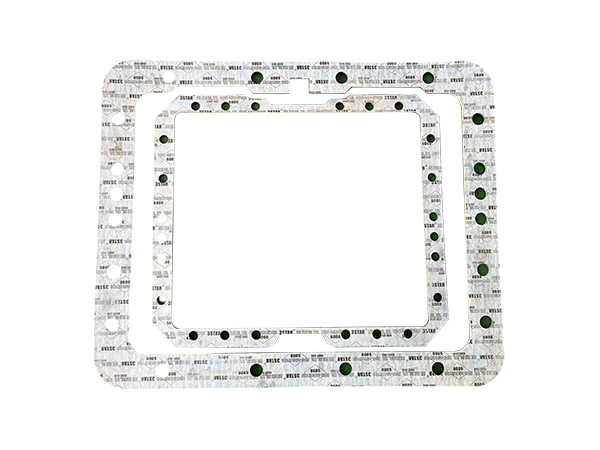

Wave-tooth composite gasket is processed into concentric wave-shaped rings by molding, rolling or turning processes, and non-metals such as expanded graphite or tetrafluoro are pasted on the surface. It is aimed at those places with high requirements on gasket rebound. Wave-shaped gasket has excellent thermal conductivity, can meet occasions with high temperature, high pressure and easy corrosion, and has any size and optional metal material. Wave tooth composite gasket is basically a line contact sealing gasket, which is mechanically supported by corrugations. Its resilience performance is determined by the adopted form, metal thickness, corrugation spacing and corrugation height. Graphite layers are generally pasted on both sides of the wave tooth gasket, which can be used for less smooth sealing surfaces. This product is renewable in general applications, quite economical and effective. Can directly replace the winding gasket and coated gasket use. Suitable for high temperature and high pressure occasions such as pressure vessels, heat exchangers, valves, pipelines and other flange connection seals.

Generally, precision lathe is used to process the two sides of the metal stainless steel flat gasket into concentric grooves. According to different media, flexible graphite, PTFE, asbestos-free board or other soft metals can be selected and pasted on the two sides of the gasket. It can also be used directly without a sealing layer, and can achieve a good sealing effect, but it is easy to cause loss to the surface of the flange in high-pressure situations.

Previous

Consultation