The difference between metal wound gasket and graphite wound gasket

2023-12-07

There is no wound gasket of pure metal, and there is no wound gasket of pure graphite.

Only metal graphite winding gasket, in fact, is often said that the metal graphite winding gasket. Winding gasket must have metal winding belt, so it is referred to as metal winding gasket. The wound gasket must be filled with non-metal, such as graphite, sometimes called graphite wound gasket. Of course, non-metallic filler graphite, asbestos, PTFE, non-asbestos and other soft materials.

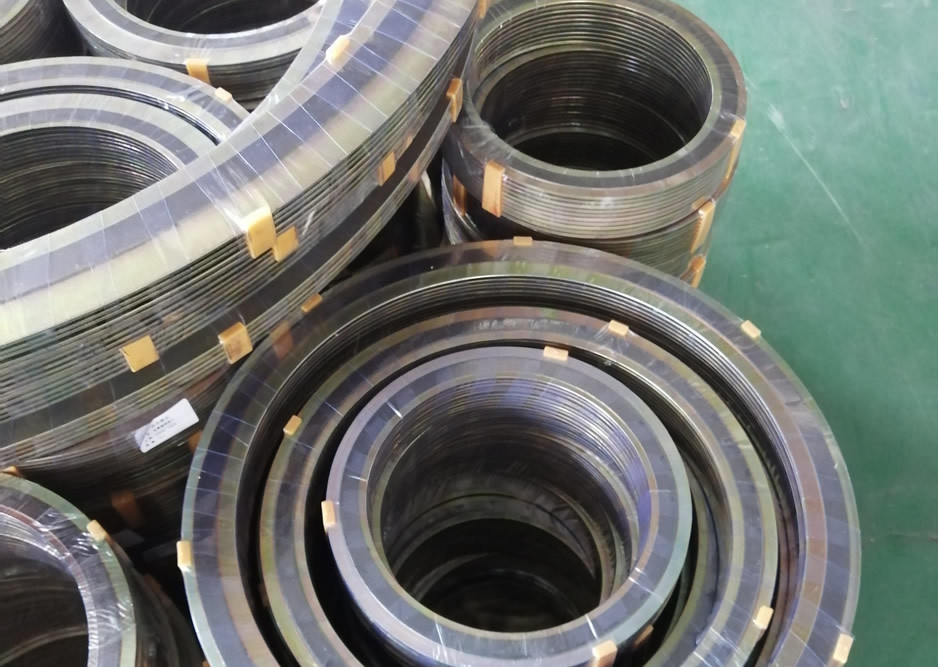

metal wound gasket:

Metal wound gasket is a kind of sealing gasket widely used at present. It is a gasket with good resilience in semi-metal sealing gasket. It is formed by replacing and winding V-shaped or W-shaped thin steel strips with different fillers. It can be used under high temperature resistance, high pressure and ultra-low temperature or vacuum conditions. By changing the material combination of the gasket, the chemical corrosion problem of the gasket by different media can be handled, its structural density can be made according to different locking force requirements. In order to strengthen the main body and accurate positioning, the winding gasket is provided with a metal inner reinforcement ring and an outer positioning ring. The inner and outer steel rings are used to control its large compression. The surface accuracy of the flange sealing surface contacted by the gasket is not high.

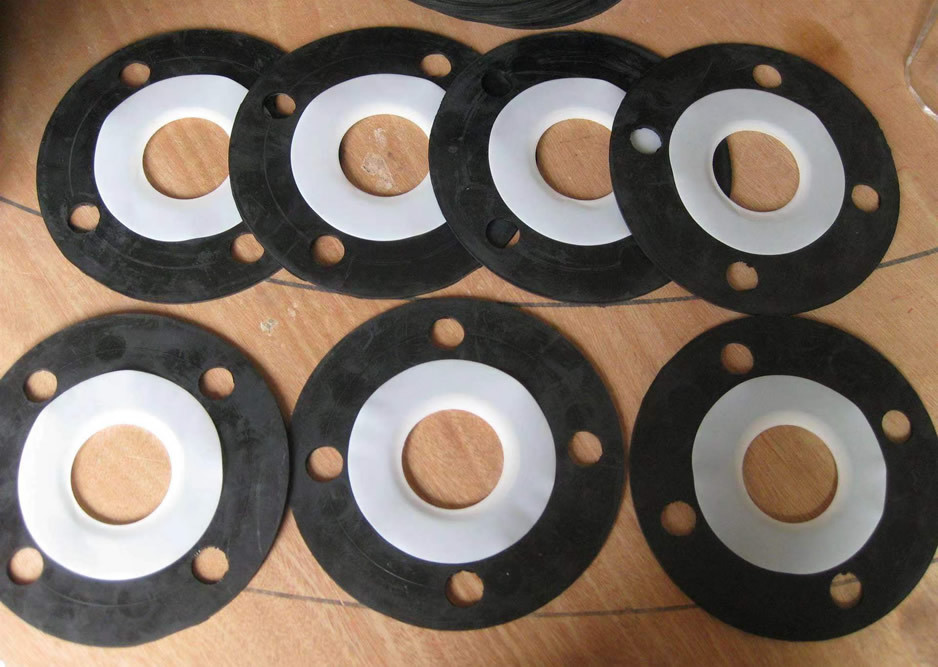

Graphite Gasket:

Graphite composite gaskets are often used for inner layer improvement materials such as ss304,ss316 or tinplate, with a thickness of 0.1~0.127mm, in the form of sprint plate improvement, mesh plate improvement and flat plate improvement. Materials are often used to improve the 304 of graphite, which can be made into different kinds of circular geometric gaskets, which are widely used in pipelines, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, refrigerators, etc. The graphite raising gasket can also be cut into complex-shaped gaskets, such as water level gauge gaskets, punched flange gaskets and cylinder gaskets for automotive diesel engines.

Graphite composite gaskets can be processed into the following forms according to the needs of use: 1. Basic graphite composite gaskets 2. Graphite composite gaskets on the inner side 3. Graphite composite gaskets on the outer side 4. Graphite composite gaskets on the inner and outer sides. Graphite composite gasket wrapping form is to maintain the excellent performance of the original gasket, and easy to install, remove, not easy to damage, but also can prevent the erosion of the media on the gasket, improve the pressure. Often use the edge material is 304 or 316 stainless steel.

1, for refractory materials: graphite and its products have high temperature resistance, high strength properties, in the metallurgical industry is mainly used to manufacture graphite crucible, often used in the steel ingot graphite protective agent, metallurgical furnace lining.

2. Conductive materials: used in the electrical industry for the manufacture of electrodes, brushes, carbon rods, carbon tubes, mercury positive current, graphite gaskets, telephone number parts, TV picture tube coating.

3. As a wear-resistant lubricating material: Graphite is often used as a lubricant in the machinery industry. Lubricating oil often can not be used under the conditions of high speed, high temperature and high pressure, and graphite wear-resistant material can be used at a high sliding speed at a temperature of 200~2023 ℃ without lubricating oil. Many corrosive medium conveying equipment, widely used graphite material made of piston cup, sealing ring and bearing, they do not need to add lubricating oil when running. Graphite milk is also a good lubricant for many metal processing (wire drawing, tube drawing).

4. Graphite has good chemical stability. After special processing of graphite, with corrosion resistance, good thermal conductivity, low permeability, it is very much used in the production of heat exchangers, reaction tank, condenser, combustion tower, absorption tower, cooler, heater, filter, pump equipment. Widely used in petrochemical, hydrometallurgy, acid and alkali production, synthetic fiber, paper and other industrial sectors, can save a lot of metal materials.

5. For casting, foundry, die pressing and high-temperature metallurgical materials: Because graphite has a small thermal expansion coefficient and can withstand rapid cooling and rapid heating changes, it can be used as a casting mold for glassware. After using graphite, ferrous metals can obtain castings with accurate dimensions, smooth surface and high yield, and can be used without processing or slightly processing, thus saving a lot of metal. Production of cemented carbide and other powder metallurgy process, the general use of graphite materials made of pressure mold and sintering porcelain boat. The crystal growth crucible of single crystal silicon, regional refining container, bracket fixture, induction heater, etc. are all processed with high purity graphite. In addition to this, graphite can also be used for vacuum smelting graphite insulation board and base, high temperature resistance furnace tube, rod, plate, grid shed and other components.

6, used in the atomic energy industry and national defense industry: graphite has a good neutron moderator used in atomic reactors, uranium graphite reactor is now a little more application of an atomic reactor. As the deceleration material in the nuclear power reactor for power, it needs to have high melting point, stability and corrosion resistance. Graphite can fully meet the above requirements. The purity of graphite used as an atomic reactor is very high, and the impurity content should not exceed tens of ppm. It is highly desirable that the boron content therein should be less than 0.5ppm. In the defense industry, graphite is also used to manufacture nozzles for solid-fuel rockets, nose cones for missiles, parts for aerospace equipment, insulation materials and radiation-proof materials.

7., graphite can also prevent boiler fouling, the relevant unit test expression, in the water to add a certain amount of graphite powder (about 4 to 5 grams per ton of water) can prevent the boiler surface scaling. In addition to this, graphite coated on metal chimneys, roofs, bridges, pipes can be anti-corrosion and anti-rust.

8. Graphite can be used as pencil lead, pigment and polishing agent. After special processing, graphite can be made of different special materials for the relevant industrial sectors.

9. Electrode: How can graphite replace copper as electrode

Graphite performance advantage is relatively large, the overall graphite composite gasket is relatively good. If you don't understand or don't understand, please consult Pingdingshan xinruida graphite manufacturing co., ltd.-graphite composite gasket-graphite products-graphite processing

Graphite wear graphite ring with what material to do the best?

2024-04-28

Precautions for installation of metal wound pad with inner and outer ring

2023-12-07

Performance and use of tetrafluoro asbestos pad

2023-12-07