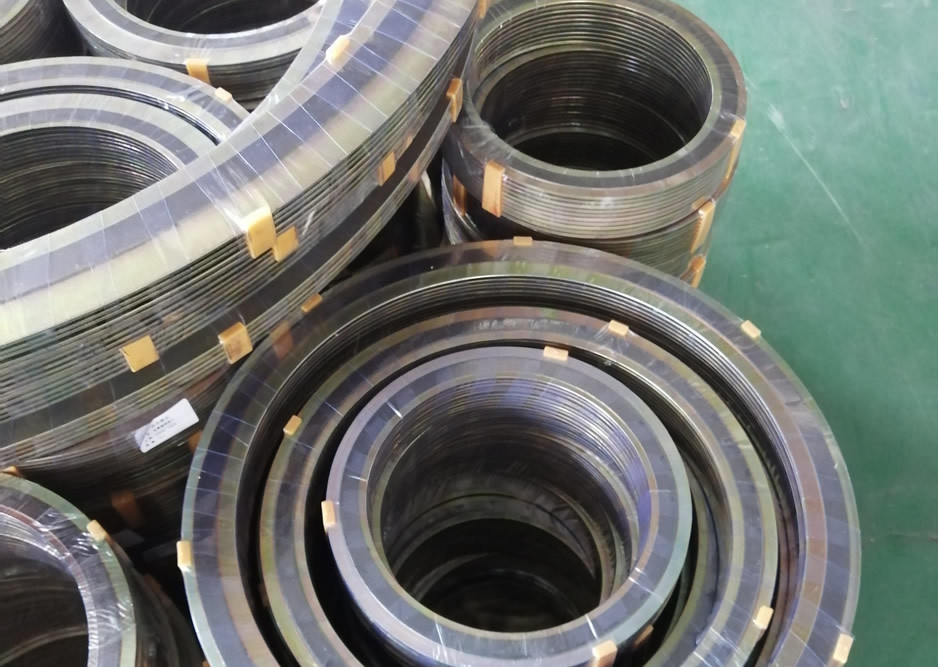

Precautions for installation of metal wound pad with inner and outer ring

2023-12-07

The metal wound gasket is made of stainless steel strip and graphite paper, and the seal has good sealing performance. The stainless steel strip contains nickel and has corrosion resistance. The nickel content of 304 stainless steel strip and 316 stainless steel strip is 9% and 14% respectively.

Features of metal wound gasket:

1. Good compression and rebound performance;

2. Multi-channel sealing and certain self-tightening function;

3. It is not very sensitive to the surface defects of the flange compression surface, and the flange sealing surface is not bonded, which is easy to center and easy to disassemble;

4, can partially eliminate the impact of pressure, temperature changes and mechanical vibration;

5, in high temperature, low pressure, high vacuum, shock and vibration cycle of a variety of harsh conditions, to maintain its good sealing performance.

What is the reason for the loss of sealing effect of metal wound gaskets:

1. The pre-tightening force is uneven or too large during installation: this will cause excessive compression of the gasket, which will cause the gasket body to yield greatly, the resilience performance will be significantly reduced, and the sealing performance will be significantly reduced. The elasticity and sealing performance of the gasket can be ensured by grasping the proper pre-tightening force during installation. The bolts should be fastened diagonally first, and then the bolts should be tightened separately after being tightened for one week;

2. The metal wound gasket is not cleaned: if it is found that the metal wound gasket has dirt, it should be thoroughly cleaned, otherwise it will affect its performance, produce leakage, and lose the sealing effect of serious flowers;

3. The ellipticity error of flange diameter has not been corrected: after installation, the sealing surface of the metal winding gasket will be exposed, which will reduce the size of the sealing joint surface and become a potential leakage point;

4. Incorrect installation: The end is installed flat as a whole. Special attention is paid to the large-size metal wound gasket with wide sealing surface. After installation, the plane should be moved to correct the warping phenomenon during installation.

Since the metal wound gasket was invented in the early last century, it has been widely used as a gasket. It has good compression performance and rebound performance. At first, in order to adapt to the working conditions of industrial development, it solves the sealing problem that other gasket types cannot solve under fluctuating pressure and temperature load conditions. Its V-shaped metal winding belt can ensure good resilience when stress is released, the non-metallic packing belt ensures the air tightness and reduces the prestress requirements of the gasket. After the metal winding gasket is introduced into China, due to the good grade of flexible graphite in China and the world's graphite reserves, the domestic metal graphite winding gasket is not only widely used in China, but also exported abroad in large quantities.

Graphite wear graphite ring with what material to do the best?

2024-04-28

Precautions for installation of metal wound pad with inner and outer ring

2023-12-07

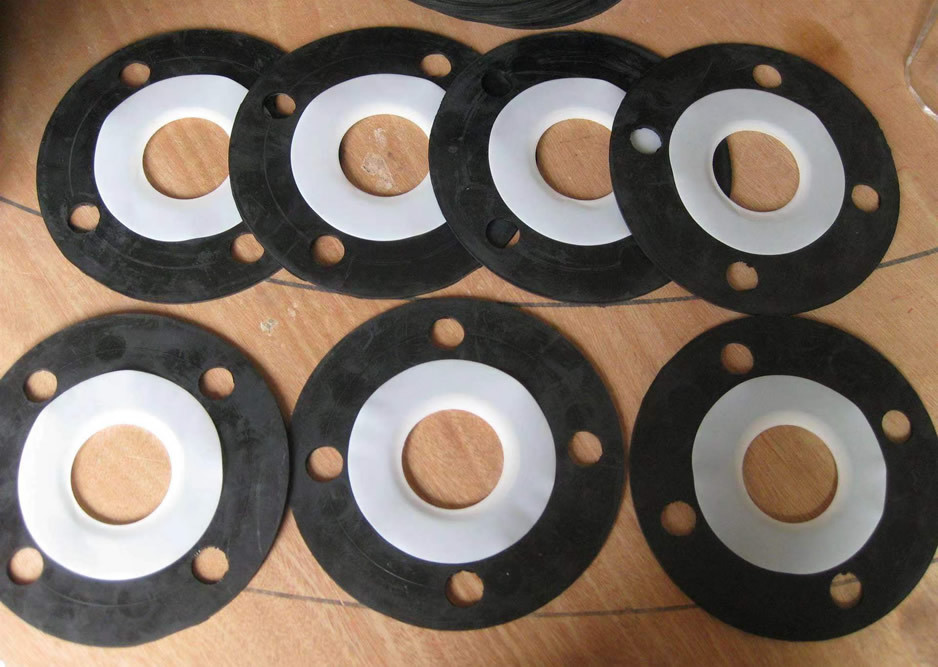

Performance and use of tetrafluoro asbestos pad

2023-12-07